In the industrial sector, lighting is a critical component that impacts both operational efficiency and workplace safety. However, traditional lighting systems can be significant energy consumers, leading to high operational costs. Transitioning to energy-efficient industrial lighting not only reduces energy consumption but also results in substantial cost savings. This blog explores the benefits, technologies, and strategies of implementing energy-efficient lighting solutions in industrial environments to pave the way for a brighter, more sustainable future.

Industrial facilities often operate around the clock, requiring extensive and reliable lighting. This constant demand makes lighting one of the largest consumers of energy in these environments. Here are a few reasons why energy-efficient lighting is crucial:

Several advanced lighting technologies have emerged to enhance energy efficiency in industrial settings. Here are some of the most impactful ones:

1. LED Lighting

Light Emitting Diodes (LEDs) have revolutionized the lighting industry due to their superior energy efficiency and long lifespan. LEDs consume much less energy than traditional incandescent bulbs and last significantly longer, reducing both energy costs and maintenance expenses. Additionally, LEDs provide high-quality light with better color rendering and minimal flicker, which is crucial for tasks requiring precision.

2. Smart Lighting Systems

Smart lighting systems use sensors and controls to optimize lighting based on real-time conditions. These systems can adjust lighting levels based on occupancy, daylight availability, and specific task requirements. By automating lighting control, smart systems ensure that lights are only used when necessary, leading to significant energy savings.

3. Induction Lighting

Induction lighting is another energy-efficient option for industrial environments. These lamps are known for their long life and low maintenance requirements. Induction lighting operates without electrodes, which reduces the wear and tear associated with traditional lighting technologies. They are especially suitable for hard-to-reach areas where maintenance can be challenging.

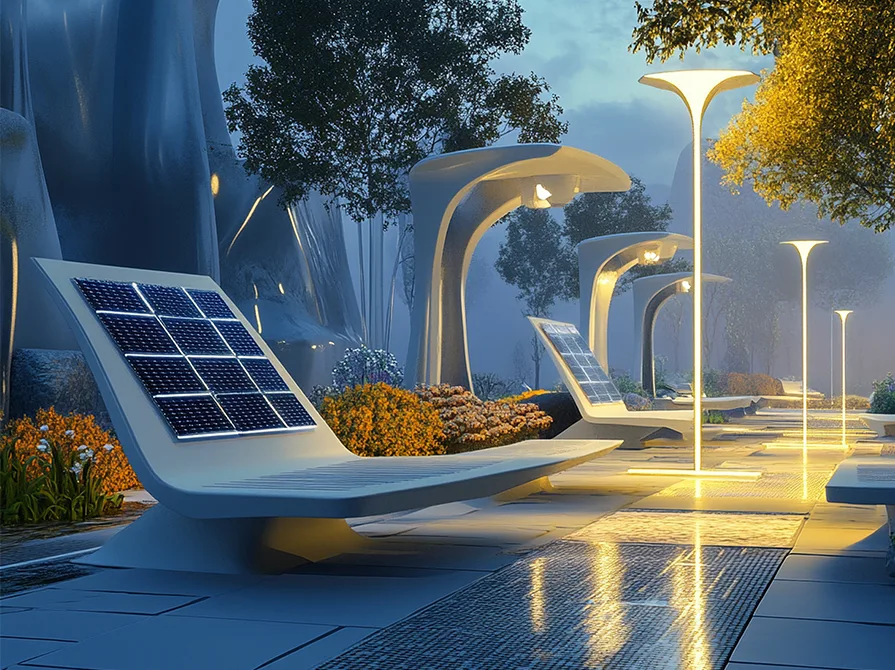

4. Solar-Powered Lighting

Solar-powered lighting systems harness energy from the sun, providing a renewable and sustainable lighting solution. While initial installation costs can be higher, the long-term savings and environmental benefits make solar lighting an attractive option for industrial facilities with outdoor areas.

5. High-Intensity Discharge (HID) Lighting

While not as efficient as LEDs, HID lamps, including metal halide and high-pressure sodium lamps, offer better energy efficiency compared to traditional incandescent and fluorescent lighting. They are often used in large spaces like warehouses and manufacturing plants where high-intensity lighting is required.

To maximize the benefits of energy-efficient lighting, industrial facilities should adopt a comprehensive approach that includes the following strategies:

1. Assessing the Existing Situation

This involves assessing the current lighting system to identify areas for improvement. This includes measuring light levels, evaluating energy consumption, and identifying outdated or inefficient fixtures. An evaluation like this provides a baseline that helps in planning and implementing energy-efficient upgrades.

2. Upgrade to Energy-Efficient Fixtures

Replacing outdated lighting fixtures with energy-efficient alternatives is the most direct way to reduce energy consumption. LEDs and other efficient lighting options should be prioritized. Consider upgrading in phases if budget constraints exist, starting with high-usage areas to maximize immediate savings.

3. Implement Smart Controls

Integrating smart controls, such as motion sensors, daylight sensors, and programmable timers, can significantly reduce energy wastage. These controls ensure that lighting is used only when needed and adjusted according to ambient light conditions. Smart lighting systems can be centrally monitored and controlled, providing further opportunities for optimization.

4. Optimize Lighting Design

Effective lighting design is crucial for maximizing energy efficiency. This involves strategically placing lighting fixtures to ensure uniform illumination and minimize shadows. Task-specific lighting should be employed where higher light levels are necessary, while ambient lighting can be kept at lower levels. Reflective surfaces and light-colored walls can also enhance the effectiveness of lighting.

5. Maintain and Monitor the Lighting System

Regular maintenance ensures that lighting systems operate at peak efficiency. This includes cleaning fixtures, replacing faulty components, and adjusting settings as needed. Monitoring energy consumption and light levels can help identify issues early and ensure the lighting system remains optimized.

Adopting energy-efficient lighting solutions in industrial environments offers numerous benefits.

1. Financial Savings

The most immediate benefit of energy-efficient lighting is the reduction in energy costs. Lower electricity bills and reduced maintenance expenses contribute to significant long-term savings. These savings can be reinvested in other areas of the business to further enhance operations and profitability.

2. Enhanced Safety and Productivity

Improved lighting quality enhances visibility, reduces the risk of accidents, and ensures a safer working environment. Better-lit workspaces also improve worker productivity by reducing eye strain and fatigue. This leads to fewer errors and higher-quality work.

3. Environmental Sustainability

Energy-efficient lighting solutions contribute to environmental sustainability by reducing energy consumption and greenhouse gas emissions. This aligns with corporate social responsibility goals and helps industrial facilities comply with environmental regulations and standards.

4. Compliance with Regulations

Many regions have regulations and standards related to energy efficiency and workplace safety. Implementing energy-efficient lighting helps industrial facilities comply with these requirements, avoiding potential fines and enhancing their reputation as responsible and sustainable businesses.

5. Future-Proofing the Facility

As technology advances, energy-efficient lighting solutions will continue to evolve. By adopting modern lighting technologies and practices, industrial facilities can future-proof their operations, ensuring they remain competitive and adaptable to future challenges and opportunities.

Energy-efficient industrial lighting is a critical component of modern industrial operations, offering substantial financial, operational, and environmental benefits. By adopting advanced lighting technologies and implementing comprehensive strategies, industrial facilities can significantly reduce energy consumption, enhance safety, and improve productivity. The transition to energy-efficient lighting is not just a cost-saving measure; it is an investment in a brighter, more sustainable future for the industrial sector. Get in touch with us to know more about our unique solutions that help you enlighten your industrial environments while also ensuring maximum cost savings.